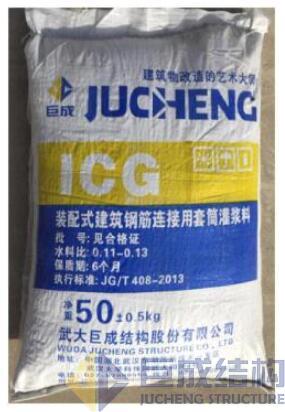

Sleeve Grouting Material for Connecting of ICG Steel Bar

Material Profile

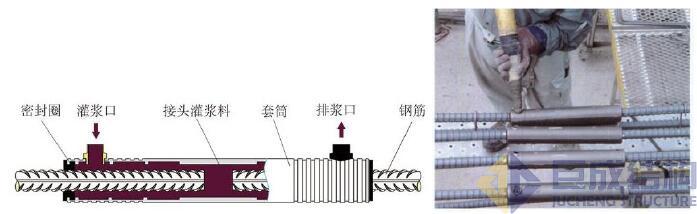

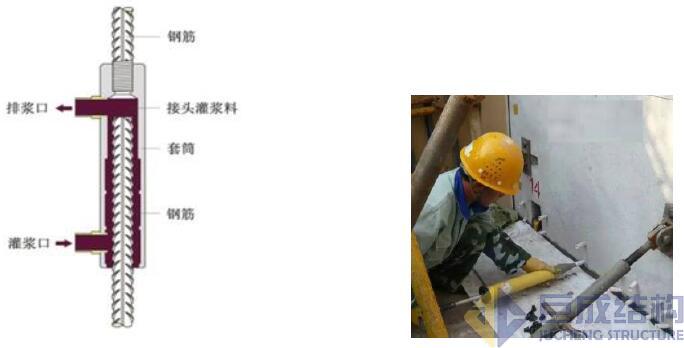

Sleeve Grouting Material for Connecting of ICG Steel Bar, a cement-based grouting material with high-grade cement as cementing material, high-grade sand mixture as aggregate, chemical admixtures and performance-tuning mineral materials, is featured with high self-flow, self-compaction, slight expansion, early strength, high strength and others. The new mixture of self-flow, self-compaction, early strength, high strength and no shrinkage after hardening has strong bond stress with reinforcing steel bars and excellent adhesion with the old concrete interface, and can be densely filled in the gap between sleeves and rebars. Its performance indicators meet the requirements of industrial standard JG/T 408-2013"Sleeve Grouting Material for Connecting of ICG Steel Bar".

Performance Feature

1. Self-flow and self-compaction: It can be densely filled in the gap between rebars and the steel sleeves.

2. Early strength, high strength and lasting high strength.

3. Slight expansion: It will improve the anchorage force and ensure the tight combination of steel bars and sleeves.

4. Durability: Resistance against crack, seepage and chemical corrosion, and high temperature (300℃).

Application Field

1. Sleeve Grouting Material for Connecting of ICG Steel Bar is applied to prefabricated concrete structures.

2. Grouting for anchor bolts of large-scale equipment.

Construction Technology

Material Consumption

1. The mix ratio of water and dry powder is 0.11 ~ 0.13, that is, 1.0kg dry powder is matched with 0.11 ~ 0.13kg water.

2. Each 1 L of space is grouted with 2.2kg dry powder of Sleeve Grouting Material for Connecting of ICG Steel Bar.

Package and Storage

It is a hydraulic and active powder material packed with moisture-proof compound bag (50 kg/bag NW). It should be kept in dampproof, waterproof, dry and sealed condition with 6 months shelf life.

Application Case

Prefabricated sample house in South Africa